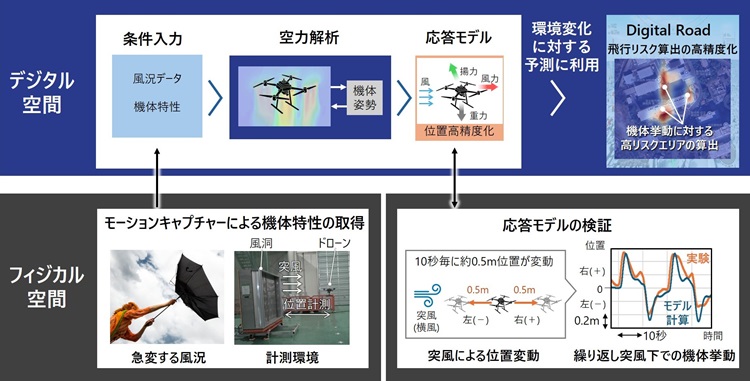

Hitachi’s new drone wind modeling technology makes small drones safer in sudden gusts and strong winds. It measures each aircraft’s wind resistance, builds a digital response model and lets teams test flights in a virtual space. As a result, operators can verify behavior with high precision before deployment in Japan’s dense cities and mountainous corridors [1]. The capability is integrated into Hitachi’s Digital Road mobility control platform for route‑level risk management.

Key Facts

- Method: wind‑tunnel tests plus motion‑capture produce aircraft‑specific drone wind modeling profiles [1].

- Accuracy: about 90% prediction of position variation under repetitive gusts, validated against simulated route meteorology [1].

- Platform: integrated with Digital Road for real‑time environment mapping and safe‑path calculation [3].

- Context: technical details presented at the Japan Society of Mechanical Engineers Annual Meeting, 7–10 Sept. 2025 [4].

Why this matters for infrastructure and logistics

Japan’s infrastructure managers face ageing assets, complex terrain and a shrinking workforce. Small drones already survey dams, levees and bridges. However, a sharp gust can still push vehicles beyond safe limits. With drone wind modeling, operators simulate site‑specific wind fields, estimate deviation and pick waypoints that keep aircraft inside controllable envelopes. Consequently, sortie completion rates rise in urban canyons, valleys and coastal corridors where legacy tools struggle with local wind gradients [5].

Digital Road functions as a practical operations hub. It fuses weather, communications coverage and terrain into a 4D map. Then it overlays each aircraft’s modeled gust response. Teams trial plans in a digital twin, compare routes and time windows, and only then release live flights. As a result, they see fewer aborted sorties, fewer manual interventions and clearer evidence for regulators [6].

“By combining wind‑tunnel dynamics with motion‑capture data, we can predict position drift with roughly 90% accuracy under repetitive gusts and verify aircraft behavior in virtual space before deployment.”Hitachi technical summary (2025) [1].

How the model works

The development team runs repeatable gust profiles in a wind tunnel and records attitude and position with motion‑capture. Next, aerodynamic analysis splits forces—wind load, lift and gravity—into an aircraft‑specific response model. When embedded in a route simulator, this drone wind modeling predicts yaw, pitch and drift in transient gusts. Therefore, planners can set headings, altitudes and speeds that preserve control margins.

Importantly, the approach is airframe‑agnostic. It supports different planforms and payloads. In real fleets, a camera gimbal, LiDAR pod or cargo crate can shift the center of mass and change cross‑sectional area. Accordingly, modeling those changes keeps the simulator truthful and the mission plan conservative.

From lab insight to route design and mission assurance

Once a platform’s response is characterized, dispatchers feed forecasts, building geometry and terrain into Digital Road. The system evaluates corridors over time, flags turbulent shear and proposes alternates. That is where drone wind modeling delivers value: it turns “fly and hope” into parameter‑driven route design with auditable safety cases—vital for utilities, rail operators and highway agencies.

In practice, the same tools help sequence multi‑site inspections. If drift risk exceeds thresholds at noon along a river levee, the model shifts that task to late afternoon. Meanwhile, a bridge span inspection moves to the morning when heat‑island effects are milder. Over hundreds of missions, these small choices lower costs and raise asset coverage.

Regulatory and ecosystem implications

For beyond visual line of sight (BVLOS) waivers, evidence matters more than ambition. Drone wind modeling supplies measurable margins against gust‑driven excursions, which strengthens safety cases near people and critical infrastructure. Moreover, it aligns with Japan’s mobility‑DX agenda that promotes risk‑aware automation across modes [7]. Expect spillovers into eVTOL and emergency response, where weather often sets feasibility limits.

Across industry, the frontier is shifting from hardware alone to integrated software, data and operations. Hitachi’s Digital Road embodies that shift—an orchestration layer where drone wind modeling sits beside communications monitoring and geofencing to raise safety and efficiency.

Use cases across critical infrastructure

Utilities can schedule powerline patrols in windy valleys with fewer scrubbed flights. Water agencies can map dams and spillways between squalls without exposing crews. Railway and highway authorities can extend corridor coverage during seasonal gusts. In each case, drone wind modeling reduces uncertainty and helps scarce technicians prioritize the right missions at the right times.

For renewable energy, the same toolkit supports maintenance of wind and solar facilities, which are central to Japan’s carbon‑neutral pathway. Accurate drift prediction tightens keep‑out margins around turbine towers and blades. Consequently, downtime drops and inspection throughput rises [8].

Editor’s analysis: what to watch next

Model portability. As more airframes are profiled, shared parameter sets may emerge. If standards bodies formalize exchange formats, drone wind modeling could plug directly into OEM simulators and UTM providers.

Autonomy hooks. Pairing gust‑response models with onboard estimators lets autonomy stacks pre‑bias control laws when entering known turbulent cells. Therefore, tracking becomes smoother and surprises fewer.

Certification data. Regulators may accept simulator‑based evidence for specific mission classes. If that occurs, expect mission‑assurance dashboards that show drone wind modeling margins as green, yellow or red bands along routes.

Related coverage

For a broader view of autonomy and robotics in land operations, see our analysis on AI‑enabled ground systems [9]. While domains differ, the same model‑driven planning is reshaping missions across air, land and maritime.

Further Reading

- Hitachi press release (JP): modeling tech for safe drone ops in strong winds [1]

- JSME 2025 Annual Meeting schedule (includes 7–10 Sept. 2025) [4]

- Hitachi: mobility control infrastructure (Digital Road lineage) [3]

- Hitachi R&D overview of mobility control and 4D environmental data [6]

References

[1] Hitachi, Ltd. (JP) news release (Sept. 4, 2025): “航空機の挙動を再現するモデリング技術…”

[3] Hitachi (Mar. 18, 2024): Mobility control infrastructure achieving high safety/efficiency in transport—Digital Road foundation.

[4] Japan Society of Mechanical Engineers: Mechanical Engineering Congress, 2025 Japan (7–10 Sept. 2025).

[5] Hitachi Drone Solutions: inspection and data‑management offerings for infrastructure operators.

[6] Hitachi R&D essay: cyber‑physical mobility control and 4D environmental data platform.

[7] METI mobility‑DX strategy document (policy context for risk‑aware automation).

[8] Hitachi Power Solutions case: drones and AI for wind‑power maintenance and decarbonization.

[9] Defence Agenda internal coverage on AI and robotics in land defence (internal link).