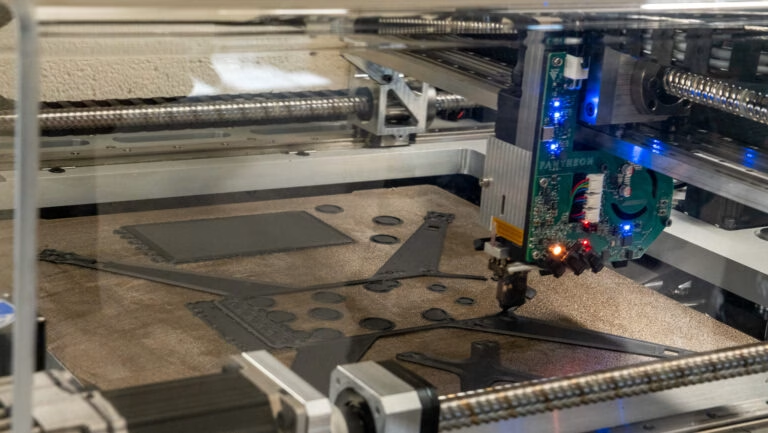

From Prototypes to Production-Scale Manufacturing

At the GVSETS 2025 conference, Army leaders detailed their plan to expand additive manufacturing. Randl Besse, commodity manager at the Rock Island Arsenal Joint Manufacturing and Technology Center (RIA JMTC), confirmed that over 1,500 parts have already been printed for Army vehicles and systems.

“We are walking now, but we will be running very soon,” Besse said. He added that the Army could soon produce 10,000 drone bodies a month, matching the global demand for affordable unmanned aerial systems. This output would mark a major leap from limited prototype runs to continuous production.

Beyond Repairs: Fully Qualified 3D Printed Components

Jason Duncan of TACOM’s Integrated Logistics Support Center said the next step is to shift from basic repair work to certified part production. As a result, 3D printed components will meet the same standards as those made with traditional methods.

The Army is leveraging its diverse portfolio of additive manufacturing systems and plans to procure more advanced capabilities. Brandon Pender of DEVCOM GVSC invited industry partners to collaborate through cooperative R&D agreements, offering access to Army laboratories, machines, and testing facilities. These collaborations could produce large-scale components from aluminum and advanced alloys.

Digital Blueprints to Eliminate Obsolescence

A key innovation is the creation of a digital ID for each 3D printed part. This “digital recipe” enables on-demand production anywhere in the world, eliminating the need for legacy tooling and mitigating supply chain disruptions. Once digitally validated, these parts could permanently solve the obsolescence problem, ensuring operational readiness even in contested environments.

As military logistics evolve toward more agile and distributed models, the US Army’s commitment to scaling 3D printing reflects a broader trend: reducing dependence on lengthy supply chains and accelerating battlefield innovation.

Strategic Implications for Defence and Aerospace

This rapid adoption of additive manufacturing aligns with NATO’s broader push for resilient defense supply chains and technological interoperability. By embedding digital manufacturing into its operational doctrine, the US Army is setting a precedent for allied forces to follow.

Read more on additive manufacturing in military logistics for insights into how this technology is reshaping defense readiness.