AI in Aerospace Aftermarket Services

Meta Description: Discover how AI is transforming aerospace aftermarket services with predictive maintenance, flight optimization, and resource management.

Artificial Intelligence (AI) is reshaping the aerospace and aviation sectors, delivering unprecedented gains in operational efficiency, safety, and cost management. Within aerospace aftermarket services, AI is revolutionizing how companies handle flight operations, capacity planning, predictive maintenance, and inventory optimization. These advancements are setting a new standard for how the industry operates in an increasingly data-driven environment.

AI and Digital Transformation in Aerospace

AI’s integration into aerospace operations is part of a broader digital transformation driven by computing power, cloud systems, and machine learning. In aftermarket services, AI enables the processing of vast data streams from aircraft systems, operational records, and external factors like weather or traffic. These insights allow decision-makers to act with speed and precision, improving both safety and efficiency.

Operational Flight Management

AI systems enhance flight planning, scheduling, and in-flight adjustments. By analyzing real-time data on weather, air traffic, and aircraft performance, AI suggests optimal routes, minimizes delays, and reduces fuel burn. Delta Air Lines’ AI-driven delay prediction tool is a prime example—using historical and live data to proactively adjust schedules.

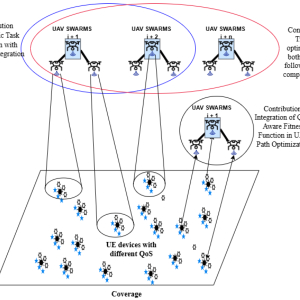

Capacity Management

Forecasting passenger demand is vital for efficient capacity management. AI models analyze booking trends, seasonal patterns, and economic factors to match resources with demand. In manufacturing, similar models predict spare part requirements, ensuring production aligns with market needs without creating costly overstock or shortages.

Predictive Maintenance

Predictive maintenance powered by AI prevents failures before they occur. By monitoring aircraft sensor data, AI detects anomalies that may indicate future breakdowns. Boeing’s use of AI on the 737 MAX is a case in point—allowing early repairs, reducing downtime, and extending asset lifespans while enhancing passenger safety.

Inventory Optimization

AI-driven inventory systems forecast part demand and optimize stock levels. Rolls-Royce’s “TotalCare” program predicts replacement needs, ensuring parts are available precisely when required. This approach reduces delays, streamlines supply chains, and boosts operational readiness across fleets.

The Future of AI in Aftermarket Services

The next phase will see AI integrate with IoT, blockchain, and 5G for real-time monitoring and automated service delivery. Digital twin technology will further allow continuous simulation and optimization of aircraft systems, expanding AI’s role from maintenance prediction to performance enhancement and even autonomous repairs.

As aerospace competition intensifies, AI adoption in aftermarket services will define market leaders. Those who leverage AI for operational precision, resource efficiency, and cost control will set the industry standard for years to come.

Further Reading: NATO Emerging and Disruptive Technologies | Transformative Role of AI in Defense and Aerospace

Tags: AI in aerospace, predictive maintenance, aerospace aftermarket, aviation AI, inventory optimization