Balancing Speed and Manufacturing Depth in Defence Industry

Key Facts

- Core Issue: Achieving equilibrium between rapid force provision and durable industrial capacity

- Strategic Relevance: Determines deterrence credibility, readiness, and long‑term sovereignty

- Critical Enablers: Digital engineering, MOSA, smart factories, skilled workforce, and mission‑oriented policy

- Target Audience: Defence & aerospace executives, program managers, acquisition professionals, and policymakers

Introduction

Modern defence ecosystems operate under a dual imperative: deliver capability at speed while building manufacturing depth that can endure shocks, sustain high‑tempo operations, and evolve across program lifecycles. This report expands the argument introduced by Defence Agenda’s analysis of strategic manufacturing and reframes it for decision‑makers who must translate doctrine into budget lines, factory throughput, and certified parts. The central thesis is simple: speed without depth burns out; depth without speed becomes irrelevant. Nations that master both gain a durable competitive edge.

Speed as a Competitive Advantage

Operational tempo and deterrence. The U.S. Department of Defense’s National Defense Industrial Strategy (NDIS) emphasises surge capacity, supply‑chain resilience, and rapid scaling to meet evolving threats NDIS release; Jan 2024 and its implementation guidance Oct 2024. These priorities mirror alliance needs where timelines for replenishment increasingly define deterrence credibility.

Design agility through open architectures. A Modular Open Systems Approach (MOSA) lets primes and SMEs insert upgrades at module level and compete components independently, accelerating refresh cycles and reducing vendor lock‑in (OUSD(R&E) MOSA guidance; 10 U.S.C. §4401).

Compressing the “design–build–certify” loop. Digital engineering and model‑based practices shorten time‑to‑field while maintaining airworthiness and safety margins. DoD’s Digital Engineering Strategy (2018) and DoDI 5000.97 (2023) institutionalise model‑centric acquisition across the lifecycle (Strategy PDF; DoDI 5000.97). NASA’s work on digital twins anchors the approach with heritage and current applications (NASA overview).

Rapid sustainment and additive manufacturing (AM). Air Force Life Cycle Management Center’s Rapid Sustainment Office has scaled AM for certified parts via the Advanced Manufacturing Program Office (AMPO), reducing downtime and parts obsolescence (AFLCMC/RSO–AMPO; USAF AM news). RAND analyses highlight AM’s implications for defence supply chains and obsolescence management (RAND 2023; RAND perspective).

Long‑Term Manufacturing Capability

Industrial sovereignty. Deep manufacturing capacity underwrites self‑reliance in prolonged crises. The European Defence Fund (EDF) co‑finances collaborative R&D to build interoperable, competitive industrial bases (EDF official; EDF Work Programme 2025). The UK’s Defence & Security Industrial Strategy (DSIS) institutionalises sovereign capabilities and multi‑year R&D signalling (DSIS overview; DSIS PDF).

Evidence‑based planning. Expenditure and trend analysis remain essential for sizing industrial baselines; the SIPRI Military Expenditure Database provides consistent long‑series for benchmarking and planning (SIPRI database; data portal).

National innovation ecosystems. Türkiye’s TÜBİTAK institutes (e.g., SAGE for defence R&D, BİLGEM for advanced electronics) supply critical technology pipelines (TÜBİTAK – EN; TÜBİTAK SAGE; TÜBİTAK BİLGEM). The SAHA İstanbul cluster orchestrates thousands of suppliers and universities across defence, aviation and space, enabling scale and certification pathways (SAHA İstanbul – EN).

Challenges and Technical Considerations

1) Technology Integration

- Digital thread & twins. Adopt authoritative models as the single source of truth across requirements, design, test, production and sustainment (DoD Digital Engineering Strategy; DoDI 5000.97). NASA’s digital‑twin work illustrates how validated virtual replicas reduce risk and cycle time (Strategy; DoDI 5000.97; NASA).

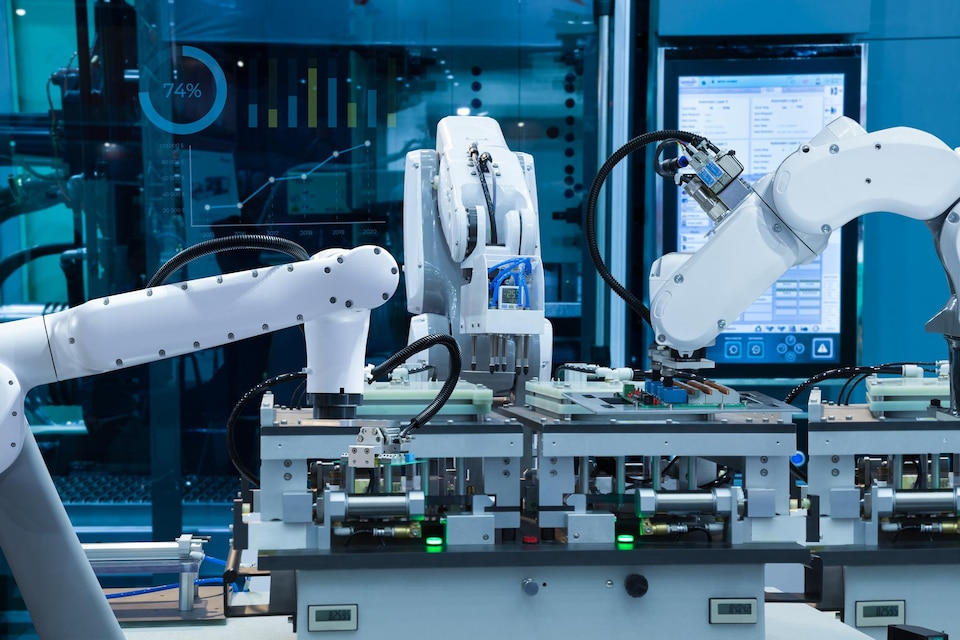

- Smart manufacturing. NIST’s smart‑manufacturing frameworks provide metrics, standards and validation pathways for cyber‑physical production systems (NIST program; analytical framework).

- Open architectures. Enforce MOSA at contract level to protect data rights and leverage open standards for avionics and mission systems (OUSD(R&E) MOSA; DLA MOSA explainer).

2) Sustainment & Readiness

- Predictive maintenance. DoD’s CBM+ doctrine moves sustainment from scheduled to condition‑based regimes, improving availability and cost per flight hour (CBM+ Guidebook 2024; DoDI 4151.22).

- AM for spares. AM combined with digital certification shortens lead times for obsolete parts; USAF’s AMPO provides governance and enterprise scaling (AFLCMC/AMPO; USAF AM news).

3) Workforce & Skills

- Skills pipelines. OECD data show transformation outpacing adult learning, reinforcing the need to scale VET, apprenticeships and mid‑career upskilling (OECD Skills Outlook 2023). In Europe, the Pact for Skills mobilises aerospace & defence large‑scale partnerships to align training with industrial demand (A&D Pact for Skills; LSP member list).

4) Collaboration & Acceleration

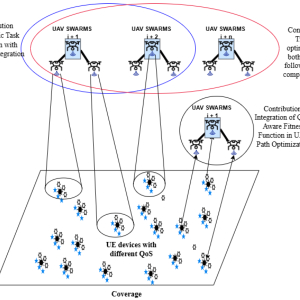

- Allied accelerators. NATO DIANA scales dual‑use deep tech across the Alliance (DIANA portal; NATO overview; 2025 challenges).

- U.S. innovation pipeline. DIU and DARPA convert commercial technologies and high‑risk research into deployable capability (DIU; About DIU; DARPA – About).

- Cluster orchestration. SAHA İstanbul demonstrates how cluster governance links OEMs, SMEs, universities and test/certification infrastructure at national scale (SAHA İstanbul – Who We Are).

Government Role and Policy Framework

Demand signalling and certainty. NDIS articulates long‑term industrial priorities and risk‑buy‑downs across the U.S. defence ecosystem (NDIS release; NDIS implementation).

Co‑funded capability building. The EDF coordinates and amplifies Member State investments in collaborative defence R&D with calls aligned to capability gaps (EDF official; EDF 2025 WP).

Sovereign capability strategies. The UK’s DSIS replaces “competition by default” with a more granular, capability‑led approach to on‑shoring critical technologies (DSIS overview; DSIS PDF).

Standards and digital policy. DoD’s DoDI 5000.97 mandates digital engineering across new programs, institutionalising model‑first practices that enable both speed and quality (DoDI 5000.97).

Strategic Outlook

A pragmatic equilibrium requires layered timelines: (1) near‑term rapid fielding and sustainment acceleration; (2) mid‑term factory digitisation and workforce scaling; (3) long‑term sovereign depth via co‑funded R&D, standards compliance, and interoperable supply networks. Organisations that operationalise MOSA, digital engineering and CBM+—while leveraging accelerators like DIANA/DIU and cluster orchestration via SAHA İstanbul—will fight tonight and manufacture smarter tomorrow.

References

- Defence Agenda – Strategic Manufacturing — https://defenceagenda.com/strategic-manufacturing/

- U.S. DoD — National Defense Industrial Strategy (release) — https://www.defense.gov/News/Releases/Release/article/3643326/dod-releases-first-ever-national-defense-industrial-strategy/

- U.S. DoD — NDIS Implementation Plan (2024) — https://www.defense.gov/News/Releases/Release/Article/3948653/dod-releases-national-defense-industrial-strategy-implementation-plan/

- OUSD(R&E) — Modular Open Systems Approach (MOSA) — https://www.cto.mil/sea/mosa/

- U.S. Code — 10 U.S.C. §4401 (MOSA requirement) — https://www.law.cornell.edu/uscode/text/10/4401

- DoD — Digital Engineering Strategy (2018) — https://ac.cto.mil/wp-content/uploads/2019/06/USA001603-18-DSD.pdf

- DoD — DoDI 5000.97 Digital Engineering (2023) — https://www.esd.whs.mil/Portals/54/Documents/DD/issuances/dodi/500097p.PDF

- NASA — Why the world (and NASA) needs digital twins — https://science.nasa.gov/biological-physical/why-does-the-world-and-nasa-need-digital-twins/

- NIST — Smart Manufacturing Program — https://www.nist.gov/smart-manufacturing

- NIST — Analytical Framework for Smart Manufacturing — https://www.nist.gov/publications/analytical-framework-smart-manufacturing

- USAF AFLCMC — Advanced Manufacturing Program Office (AMPO) — https://www.aflcmc.af.mil/WELCOME/Organizations/Rapid-Sustainment-Office/AMPO/

- USAF AFMC — AMPO tool goes live — https://www.afmc.af.mil/News/Article-Display/Article/3596924/rapid-sustainment-office-advanced-manufacturing-program-office-tool-goes-live-i/

- RAND — Additive Manufacturing (2023) — https://www.rand.org/content/dam/rand/pubs/research_reports/RRA2900/RRA2984-1/RAND_RRA2984-1.pdf

- RAND — Additive manufacturing & obsolescence (2015) — https://www.rand.org/pubs/perspectives/PE171.html

- DoD — CBM+ Guidebook (2024) — https://www.dau.edu/sites/default/files/2024-08/CBM%2B%20Guidebook%20August%202024%20-%20Stamped.pdf

- DoD — DoDI 4151.22 CBM+ (2020) — https://www.esd.whs.mil/Portals/54/Documents/DD/issuances/dodi/415122p.pdf

- European Commission — European Defence Fund (official) — https://defence-industry-space.ec.europa.eu/eu-defence-industry/european-defence-fund-edf-official-webpage-european-commission_en

- European Commission — EDF Work Programme 2025 — https://defence-industry-space.ec.europa.eu/edf-work-programme-2025_en

- UK Government — Defence & Security Industrial Strategy (overview) — https://www.gov.uk/government/publications/defence-and-security-industrial-strategy

- UK Government — DSIS (PDF) — https://assets.publishing.service.gov.uk/media/60590e988fa8f545d879f0aa/Defence_and_Security_Industrial_Strategy_-_FINAL.pdf

- SIPRI — Military Expenditure Database (overview) — https://www.sipri.org/databases/milex

- SIPRI — Data Portal — https://milex.sipri.org/

- NATO — DIANA portal — https://www.diana.nato.int/

- NATO — DIANA overview (2025) — https://www.nato.int/cps/en/natohq/topics_216199.htm

- NATO — DIANA 2025 challenges — https://www.nato.int/cps/en/natohq/news_235771.htm?selectedLocale=en

- European Commission — Pact for Skills: Aerospace & Defence ecosystem — https://pact-for-skills.ec.europa.eu/about/industrial-ecosystems-and-partnerships/aerospace-and-defence_en

- European Commission — LSP member list (A&D) — https://pact-for-skills.ec.europa.eu/document/download/e8bdafb2-7dcd-491f-9bf2-47c825d8795e_en?filename=LSP+List+Aerospace.pdf

- OECD — Skills Outlook 2023 (PDF) — https://www.oecd.org/content/dam/oecd/en/publications/reports/2023/11/oecd-skills-outlook-2023_df859811/27452f29-en.pdf

- TÜBİTAK — Homepage (EN) — https://tubitak.gov.tr/en

- TÜBİTAK — SAGE — https://www.sage.tubitak.gov.tr/en/

- TÜBİTAK — BİLGEM — https://bilgem.tubitak.gov.tr/en/

- SAHA İstanbul — Cluster (EN) — https://www.sahaistanbul.org.tr/en/