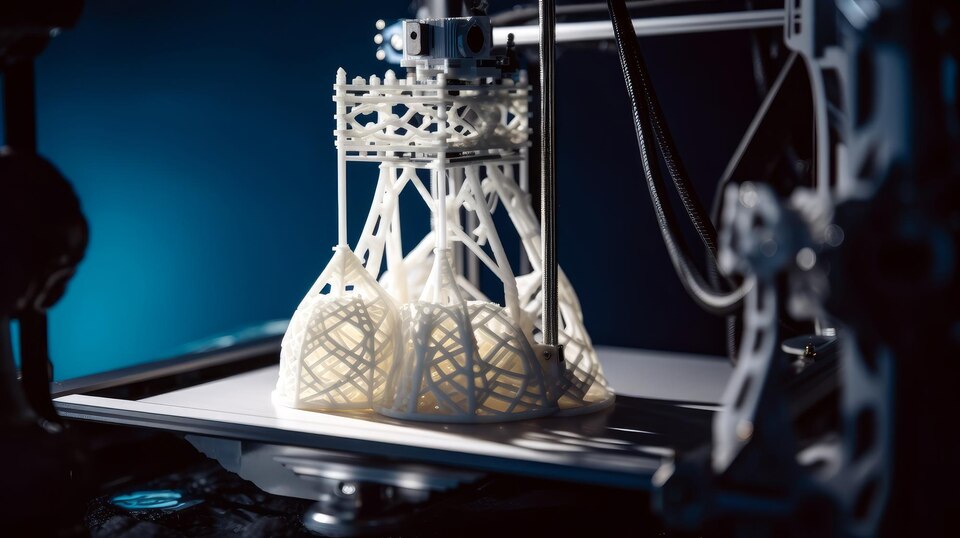

In a groundbreaking stride for naval technology, the utilization of 3D Printing Optimizes Aircraft Carrier Construction. This innovative approach not only demonstrates the maritime industry’s commitment to progress but also showcases the significant impact that technology can have on optimizing efficiency and resource utilization.

The Rise of 3D Printing in Naval Construction

Embracing Additive Manufacturing

The integration of 3D printing, also known as additive manufacturing, is rapidly gaining traction in various industries, and naval construction is no exception 3D printing optimizes aircraft carrier construction. This disruptive technology allows intricate components to be created layer by layer, translating digital designs into physical objects with unparalleled precision.

A Game-Changer in Man-Hours Savings

Naval construction projects, such as building aircraft carriers, demand extensive man-hours of labour for crafting complex components. 3D printing’s role as a game-changer lies in its ability to significantly reduce the time and effort required for manufacturing intricate parts. This translates to substantial savings in labour costs and accelerated project timelines.

Applications of 3D Printing Optimizes Aircraft Carrier

Complex Component Manufacturing

The intricate nature of naval vessels demands the production of complex components that are often labour-intensive and time-consuming to create using traditional methods. 3D printing offers a transformative solution by enabling the fabrication of intricate parts in a fraction of the time, resulting in faster assembly and reduced production costs.

H3 Title: Customization and Iterative Design

One of the key advantages of 3D printing is its versatility in creating customized components tailored to specific requirements. This flexibility empowers engineers to iterate designs rapidly, fine-tuning them for optimal performance. As a result, naval construction projects benefit from enhanced functionality and efficiency.

Future Implications and Potential

H2 Title: Redefining Naval Construction Paradigms

The successful integration of 3D printing in aircraft carrier construction sets a precedent for the future of naval technology. As additive manufacturing continues to evolve, it holds the potential to revolutionize the entire construction process, leading to streamlined operations, reduced costs, and enhanced vessel capabilities.

H3 Title: Sustainable Manufacturing Practices

Beyond efficiency gains, 3D printing aligns with the growing emphasis on sustainable practices in various industries. By minimizing material waste and energy consumption, this technology contributes to environmentally conscious manufacturing, a factor of increasing importance in the maritime sector.

FAQs (Frequently Asked Questions)

Q1: What is 3D printing in naval technology?

A1: 3D printing, or additive manufacturing, involves creating objects by layering materials based on digital designs. In naval technology, it’s being used to fabricate intricate components for vessels.

Q2: How does 3D printing save man-hours in aircraft carrier construction?

A2: 3D printing significantly reduces the time required to manufacture complex components, leading to substantial savings in labor hours and accelerated project timelines.

Q3: What are the advantages of 3D printing in naval construction?

A3: 3D printing offers customization, rapid design iteration, reduced production costs, and potential sustainability benefits in naval construction.

Q4: How does 3D printing impact the future of naval technology?

A4: The successful integration of 3D printing paves the way for more efficient, cost-effective, and capable naval construction processes.

Q5: Is 3D printing environmentally friendly in naval construction?

A5: Yes, 3D printing’s reduced material waste and energy consumption align with sustainable manufacturing practices in the maritime sector.

In conclusion, the incorporation of 3D printing technology is revolutionizing aircraft carrier construction, exemplifying the maritime industry’s adaptability and pursuit of innovation. By saving thousands of man-hours and optimizing the manufacturing process, 3D printing is shaping the future of naval technology. As this technology continues to evolve, its applications will likely extend even further, transforming the way naval vessels are designed, built, and operated.