In the ever-evolving landscape of aerospace propulsion, NASA has achieved a groundbreaking milestone with a successful test of its 3D printed Rotating Detonation Rocket Engine. This technological marvel represents a significant leap forward in propulsion systems, promising enhanced efficiency, reduced costs, and increased sustainability. In this comprehensive exploration, we delve into the intricacies of this revolutionary engine, its testing success, and the potential implications for the future of space exploration.

The Genesis of Innovation

Unveiling the 3D Printed Rotating Detonation Rocket Engine

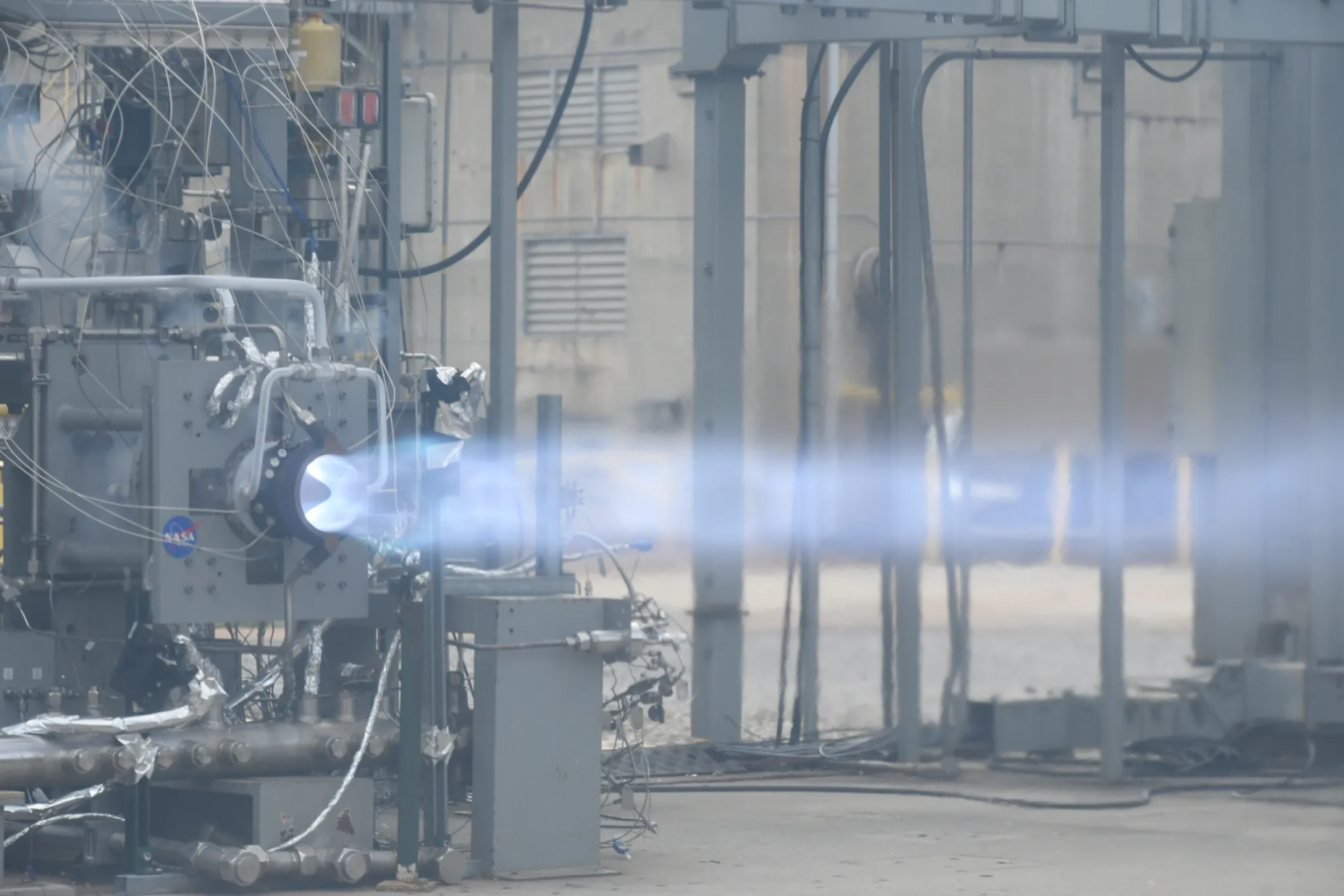

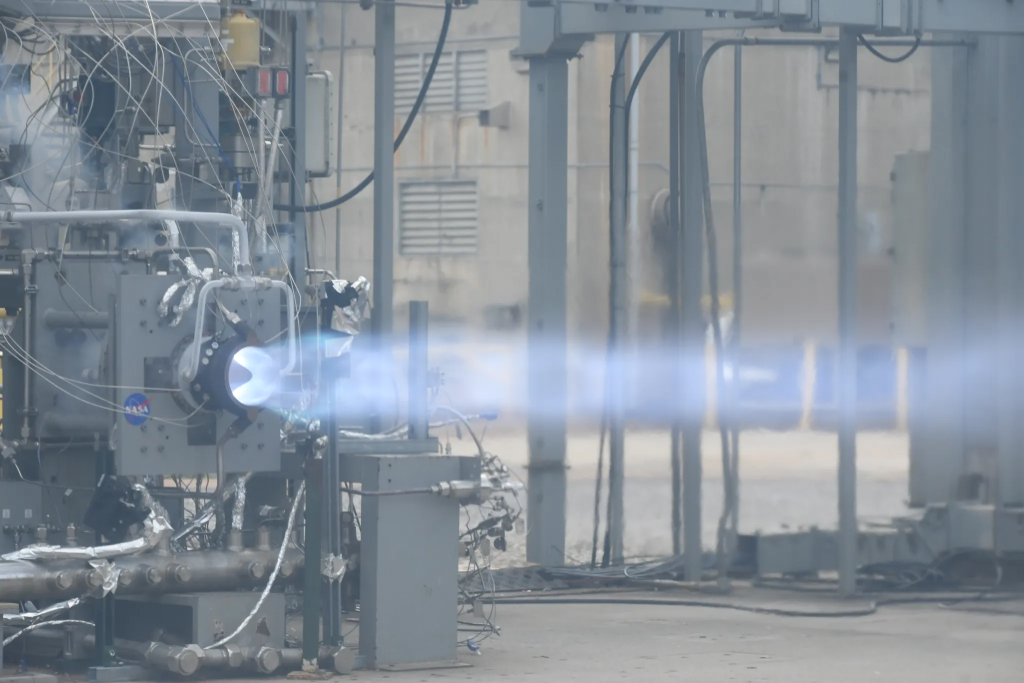

NASA’s foray into advanced propulsion systems led to the development of the 3D printed Rotating Detonation Rocket Engine. This cutting-edge engine leverages additive manufacturing techniques, allowing for intricate designs and precise construction. The utilization of 3D printing not only streamlines the manufacturing process but also enables the creation of complex geometries that enhance engine performance.

The Promise of Rotating Detonation Technology

At the heart of this innovation lies the concept of Rotating Detonation Combustion, a propulsion technique that offers unparalleled efficiency gains. Unlike traditional rocket engines, which rely on steady-state combustion, rotating detonation engines introduce a dynamic and continuous detonation wave. This not only maximizes fuel utilization but also reduces thermal stress on engine components, leading to increased longevity.

Testing Success: A Pivotal Moment

Significance of Successful Testing

NASA’s recent test of the 3D-printed Rotating Detonation Rocket Engine marks a pivotal moment in the development of advanced propulsion systems. The successful execution of the test validates the theoretical concepts behind rotating detonation technology and showcases its viability in real-world applications. This success opens the door to a new era of space exploration propelled by efficient and sustainable rocket engines.

Operational Parameters and Performance Metrics

During the test, the 3D printed Rotating Detonation Rocket Engine underwent rigorous evaluation across various operational parameters. Metrics such as thrust efficiency, fuel consumption rates, and temperature stability were scrutinized to ensure the engine’s performance met and exceeded expectations. The results not only affirmed the feasibility of rotating detonation propulsion but also demonstrated its potential to redefine the benchmarks of rocket engine efficiency.

Implications for the Aerospace Industry

Transformative Impact on Space Exploration

The successful testing of NASA’s 3D-printed Rotating Detonation Rocket Engine holds profound implications for the future of space exploration. The increased efficiency and reduced costs associated with this propulsion technology pave the way for more ambitious missions, extended space travel, and the exploration of celestial bodies previously deemed impractical.

Sustainability in Aerospace

As the global focus on sustainable technologies intensifies, the 3D-printed Rotating Detonation Rocket Engine emerges as a beacon of environmental responsibility in the aerospace industry. The enhanced fuel efficiency directly contributes to reduced carbon emissions, aligning with the industry’s commitment to environmentally conscious practices. This breakthrough sets a new standard for sustainability in rocket propulsion.

Future Prospects and Collaborative Opportunities

Scaling Up Production

Looking ahead, the challenge lies in scaling up the production of 3D printed Rotating Detonation Rocket Engines for widespread adoption. Collaborative efforts between NASA and industry partners are crucial in refining manufacturing processes, optimizing material selection, and overcoming logistical challenges. The scalability of this technology will determine its broader impact on the aerospace sector.

Collaborations with Private Sector

The success of NASA’s innovation opens avenues for collaboration with private aerospace companies. Joint ventures and partnerships can expedite the integration of the 3D printed Rotating Detonation Rocket Engine into commercial space travel, satellite deployment, and other aerospace applications. The collaboration between public and private entities is essential for maximizing the technology’s potential and fostering continued advancements.

Conclusion

In conclusion, NASA’s achievement with the 3D-printed Rotating Detonation Rocket Engine signals a paradigm shift in aerospace propulsion. The marriage of additive manufacturing and rotating detonation technology unlocks unprecedented possibilities for efficient, sustainable, and cost-effective space exploration. As we navigate the cosmos, propelled by the ingenuity of such advancements, the 3D printed Rotating Detonation Rocket Engine stands as a testament to human innovation, pushing the boundaries of what is achievable in the vast expanse of outer space.