Revolutionary materials in the aviation industry have long been at the forefront of technological advancements. Besides they are continually pushing the boundaries of what’s possible. From the first successful flight by the Wright brothers to the development of supersonic jets, aviation has been a testament to human ingenuity. Today, the industry is undergoing another transformation as revolutionary materials and techniques revolutionize aircraft construction.

In this blog post, we will take a closer look at the exciting innovations that are reshaping aircraft manufacturing. From groundbreaking materials to cutting-edge construction methods, these advancements are propelling the aviation industry into an era of unparalleled performance, safety, and sustainability.

Revolutionary Materials Transform Aircraft Construction

- Advanced Composite Materials

One of the most significant breakthroughs in aircraft construction is the adoption of advanced composite materials. These lightweight yet robust materials, such as carbon-fibre-reinforced polymers, offer unparalleled strength-to-weight ratios, making aircraft more fuel-efficient and reducing emissions. Composite materials also exhibit excellent resistance to corrosion and fatigue, contributing to the longevity and durability of aircraft structures.

- Additive Manufacturing (3D Printing)

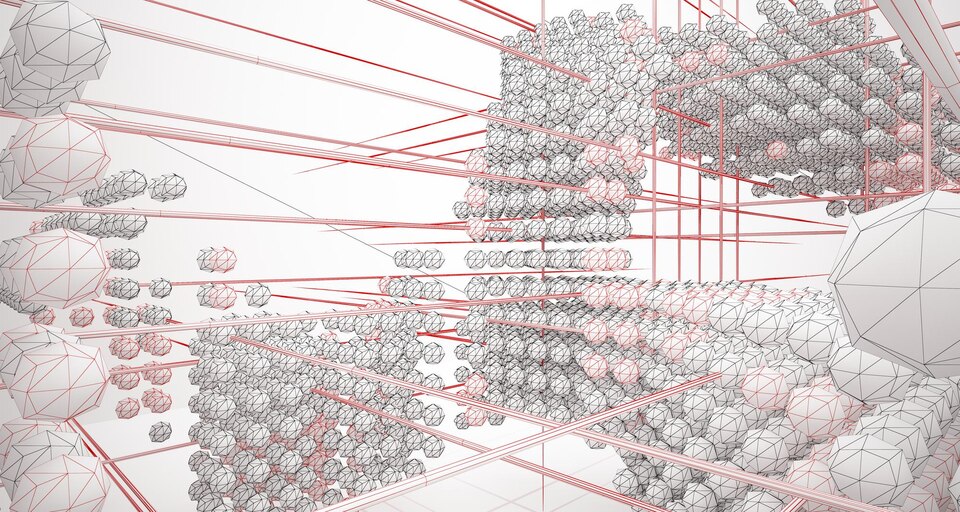

Additive manufacturing, commonly known as 3D printing, has become a game-changer in various industries, including aviation. In aircraft construction, 3D printing allows for the creation of complex, high-precision components with reduced material waste. This technology enables rapid prototyping and customization, streamlining the design and production process. From engine parts to cabin components, additive manufacturing is revolutionizing aircraft manufacturing.

- Sustainable Aviation Initiatives

As environmental concerns gain prominence, the aviation industry is actively pursuing sustainability initiatives. Aircraft manufacturers are exploring renewable and bio-sourced materials to reduce their carbon footprint. Additionally, efforts to enhance fuel efficiency and explore alternative propulsion systems, such as electric and hybrid-electric technologies, are reshaping the future of aviation.

- Intelligent Design and Simulation

Advancements in computer-aided design (CAD) and simulation technologies have revolutionized the aircraft development process. Engineers can now create highly detailed virtual prototypes, enabling them to optimize designs for maximum performance and safety. Simulation-driven design also accelerates testing and validation, significantly reducing the time and cost of aircraft development.

- Next-Generation Manufacturing Techniques

To meet the increasing demand for more sophisticated and efficient aircraft, manufacturers are embracing next-generation manufacturing techniques. Automated assembly lines and robotics are streamlining production processes, ensuring precision and consistency in every aircraft built. These technologies also improve workforce safety and productivity.

Conclusion

As the aviation industry continues to soar to new heights, revolutionary materials and cutting-edge techniques are reshaping aircraft construction. Advanced composite materials, additive manufacturing, sustainability initiatives, intelligent design, and next-generation manufacturing techniques are driving unprecedented advancements in aircraft performance, safety, and environmental impact.

With each innovation, the future of aviation becomes more promising and sustainable. As we embrace these transformative technologies, we pave the way for a new era of air travel, characterized by efficiency, safety, and environmental responsibility. The revolutionary changes underway in aircraft construction are not only shaping the aviation industry but also inspiring a world of boundless possibilities for future generations of air travel.